2026 Innovation Survey Report

AI is top of mind—but data and execution decide success. Kenco’s 2026 Innovation Survey examines how supply chain leaders are …

“Kenco understands the complexity and challenges facing supply chains. In order to provide optimal results, our Solutions Engineering Team begins every design with a focus on customer-specific requirements. Our data-driven process and approach to innovation enables the right level of automation, to deliver logistics results for our partners.”

— Felix Vicknair, Vice President of Supply Chain Solutions at Kenco Group

Kenco brings a deep understanding of every facet of the supply chain to help our clients improve supply chain networks, cut costs and minimize waste, and increase capacity to grow their businesses. Whether you’re looking to improve current warehouse operations, implement a new distribution strategy, or redesign your entire supply chain end-to-end, our team has the expertise and know-how to help achieve your goals in a timely manner.

Supply Chain Strategy

Our end-to-end supply chain strategy consulting services help customers reach peak performance, from sourcing to delivery. By combining years of experience with data-driven insights, we provide strategic recommendations for optimizing distribution networks and transportation today, while preparing businesses for tomorrow.

Our Areas of Expertise:

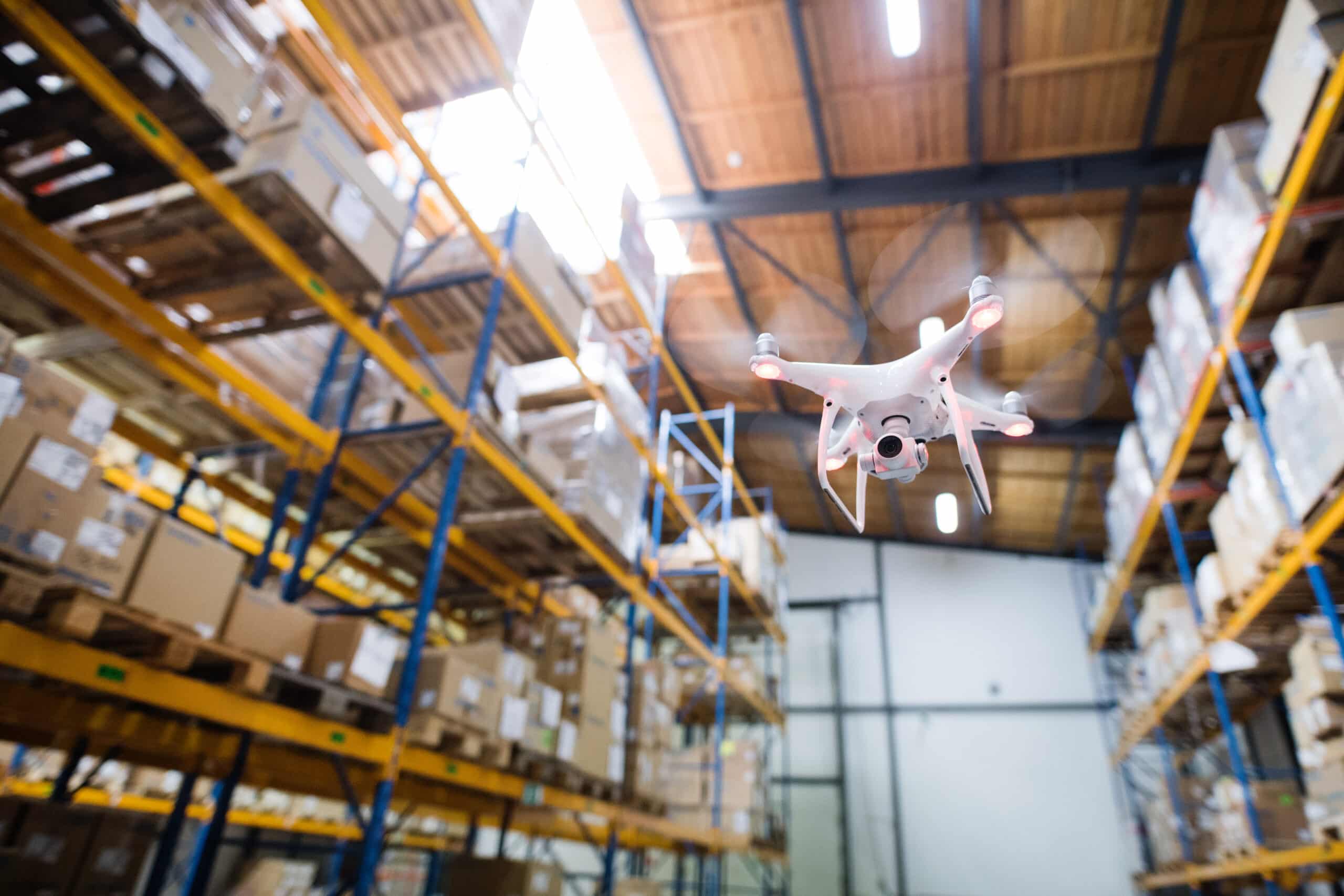

Facility Design & Optimization

Proper warehouse layout and design has the potential to accelerate throughput, shave costs, increase storage capacity, and improve safety. We take a close look at operational data, including what, when, and how inventory moves to provide the best recommendation for optimizing facility design.

Our Areas of Expertise:

Packaging Design

Inefficient packaging can be costly and wasteful. With thoughtful redesign of packaging, you can uncover opportunities to cut costs, be more sustainable, and satisfy customers.

Our Areas of Expertise:

Partner with Kenco and join the hundreds of customers who have transformed their supply chain and made a lasting impact on their businesses.