Vote For Kenco!

News

News

Automation Guidance, a service proven to save customers on average more than $2.5m annually, joins the Kenco MHE Solutions™ portfolio ...

News

Furniture manufacturer’s move from California will increase two-day service area, reduce operating costs. (more…)

News

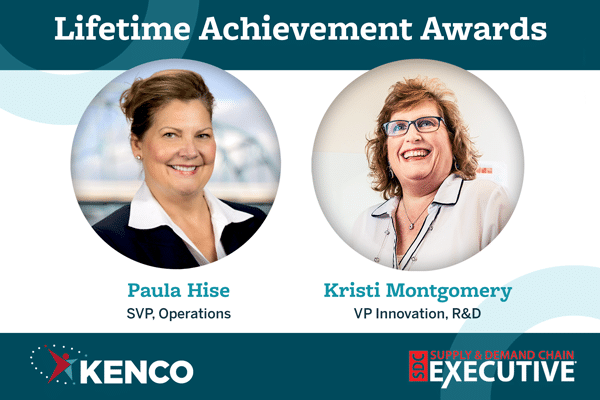

This award recognizes outstanding executives whose accomplishments offer a roadmap for other leaders looking to leverage supply chain for ...

News

CHATTANOOGA, Tenn. – January 4, 2024 - Kenco, a leading North American third-party logistics company, proudly announces the acquisition of The ...

News

CHATTANOOGA, Tenn. —April 20, 2021— Kenco Logistics, one of North America’s leading third-party logistics (3PL) providers, is proud to announce ...

News

CHATTANOOGA, Tenn. —May 4, 2021— Kenco Logistics, one of North America’s leading third-party logistics (3PL) providers, today announced the ...

News

CHATTANOOGA, Tenn.- July 2021 - Kenco Logistics, one of North America’s leading third-party logistics (3PL) providers, is proud to be deploying ...

News

IN THE PAST YEAR, KENCO HAS SEEN REMARKABLE GROWTH DESPITE THE PANDEMIC-DRIVEN HARDSHIPS AFFECTING THE GLOBE. CHATTANOOGA, Tenn. —August ...

News

New office to support continued revenue and headcount growth in western North America CHATTANOOGA, Tenn. — August 10, 2021— Kenco ...